Optical Cleaning

Although photodiodes in packages or in chip form are reasonably rugged, avoid touching the cell or package window with bare fingers.

To clean a detector, any dust or loose particles should first be blown away using dry compressed gas. The detector surface or window can then be cleaned by using a lint free swab or lens tissue moistened with isopropyl alcohol and gently wiping the element with a clean, lint free swab or lens tissue. Repeat the wiping procedure for stubborn contamination.

Electronic grade alcohol is preferred for high shunt resistance/low dark current devices without a protective cover.

Soldering

Excessive heat during soldering of package leads can cause permanent damage to the photodiode. Soldering temperature and time must be minimised to protect the diode, but must be long enough and high enough for a proper solder joint. These factors vary for each type of package.

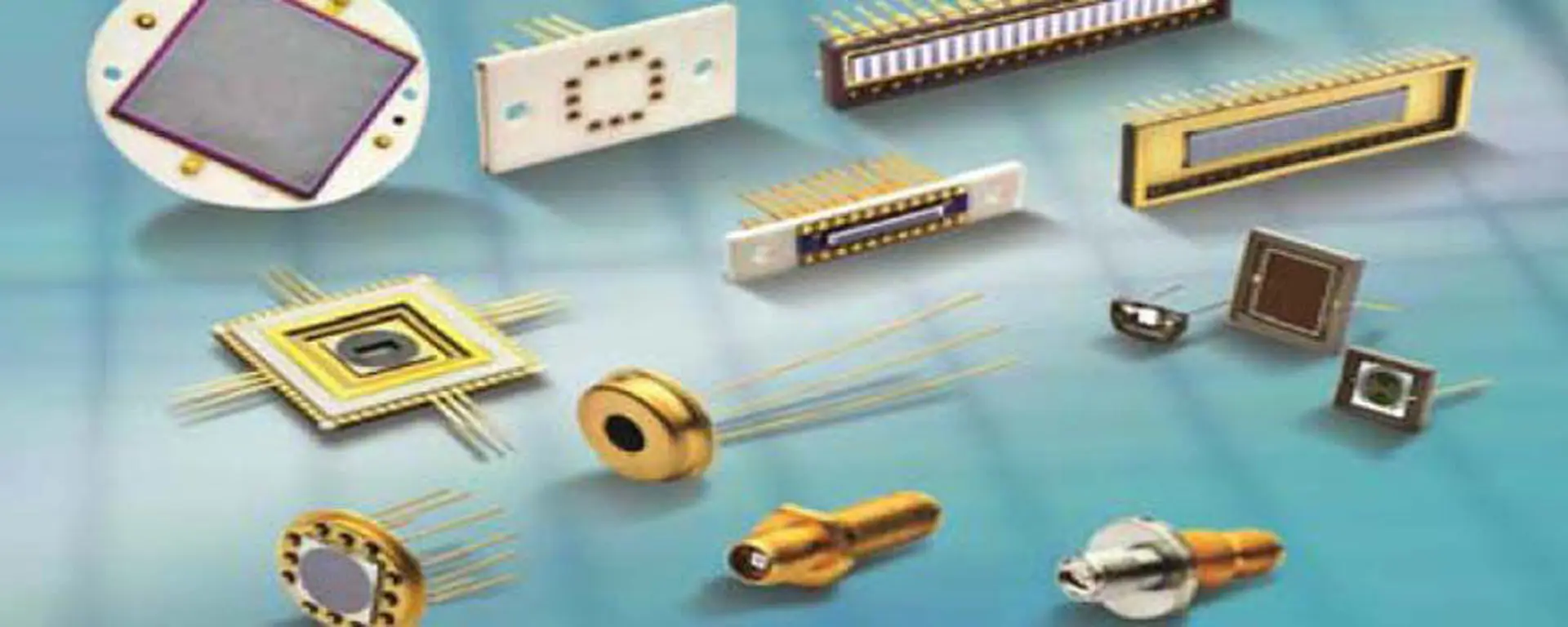

Chips with factory soldered leads can be soldered without special heating precautions. Photodiodes in metal, ceramic and plastic packages can accept progressively less heat before the device is damaged. Using 60/40 PbSn solder the maximum recommend temperature and times are 300°C for 15 seconds for metal, 300°C and 10 seconds for ceramic and 300°C for 5 seconds for plastic packages.

Package heating can be minimised by clamping a heat sink (tweezers or pliers) between die solder joint and the package.

Electrostatic Discharge Control

Photodiodes designed for very low dark currents and very high shunt resistances can be damaged by electrostatic discharge. Take standard ESD control precautions when handling these high performance devices.

Storage

Silicon die are hygroscopic and contamination sensitive. Unsealed devices or unpackaged die should be stored in a controlled, clean and dry environment to prevent degradation of performance.